Dear Sirs!

I am like you passionate about Ultralight aircraft, for a long time, and I live from this wonderful hobby!

I allow myself to ask you, because I would like to save our achievements and not see the Ultralight aircraft go to a form of LSA +/- certified, and also keep my job!

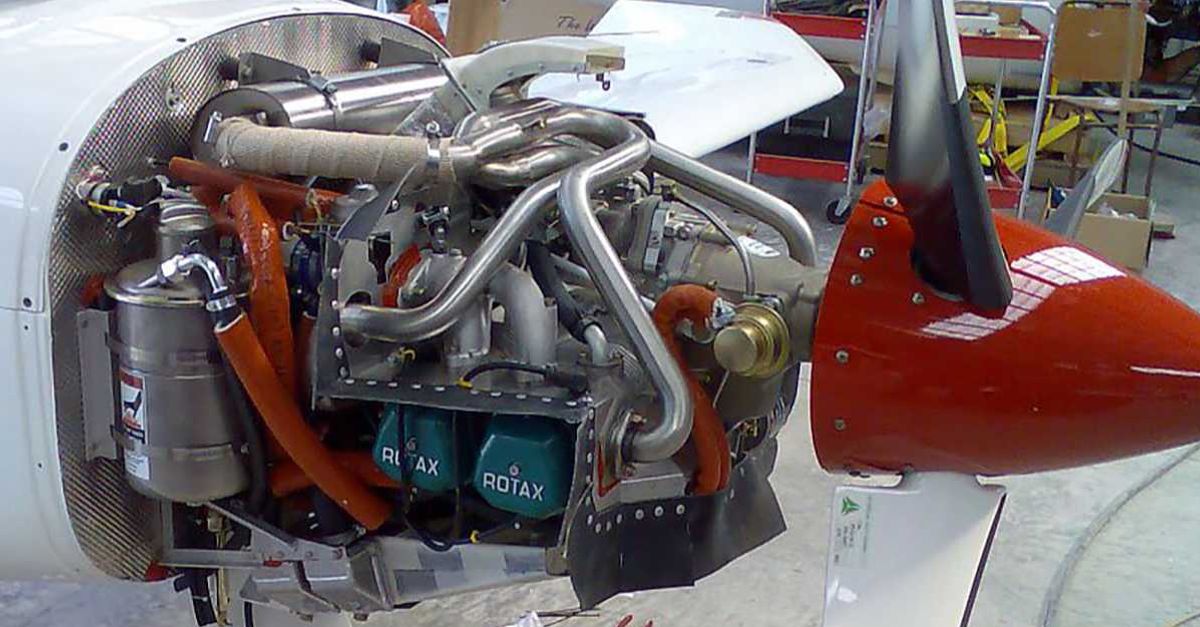

Let me explain: the 2 t rotax engines and the 912 have allowed the microlight to take off as we know however,it is towards a slow death that rotax leads us now.

The last 20 years of rotax development have not been on 4t engines replacing the old 447/503/582, nor on quieter exhaust systems, but on high end engines; heavy, complex and very expensive! ; at the last AERO show, there were only machines with 912is / 915 is, very sophisticated and impossible to be maintained by the owner...

ROTAX is the leading manufacturer with 95% of the world market for aircraft engines and microlights under 150 hp.

This Monopoly is both expensive (due to the very principle of the monopoly), and dangerous for users at the regulatory level, given the technical requirements required by this manufacturer Indeed, while the official definition of the ULM is: “a machine of simple design that can be easily maintained by its owner” but Rotax requires:

- a repairer approved by rotax and refuses to give the technical documentation necessary for the renovation (overhaul manual) to other professionals,

- original parts (although it is a non-certified engine and there are many parts of technically equivalent quality in Europe) similarly

and some recommendations or maintenance obligations do not correspond to any logic other than financial:

- the calendar term of 10 to 15 years for the 912 4-strokes, technically not justifiable given that these dry sump engines are sealed and full of oil protecting them from corrosion, and while the 582-503 2-strokes are exempt!

- the parts that must be changed at the calendar or time limit such as starter brushes, camshaft, exhaust valves can be checked easily and present no risk to be reused.

The rotax maintenance manual as it is produced, is therefore not at all in accordance with the basic principles of ULM, and it must therefore be modified !

The EMF (European Microlight Federation), must demand this from rotax quickly, because if nothing is done, case law related to accidents following engine failure (which should never happen in microlight aircraft, engine failure being part of the flight envelope) will soon oblige all ROTAX engine owners to have their engines serviced at the exclusive representative with Rotax parts exclusively, making the operating cost of the engine exorbitant and therefore will lead to a rapid decline in the ULM world...

The EMF must therefore impose on rotax a maintenance-overhaul manual accessible to all, without a rotax approved mechanic, and in accordance with ULM regulations (simple machine that can, etc.) on the other hand, the parts can be of origin or equivalent and this must be specified in this manual as well as any conforming part in metrology, must always be able to be used again.

On the other hand it is clear that the professional who wants to do engine work must have at least a mechanic cap.

The rotax microlight manual must comply with the microlight rules, our future is at stake...and our wallet!

If you want to support this European action, I invite you to sign this petition.

Claude Kieger

Manager of Loravia SAS, engine manufacturer for more than 30 years, having represented the brands Rotax - Hirth - Limbach - Simonini (and now Zongshen by Air K Motors)

-

source photo : wikipedia - HarveyStoatgobbler